Benchmark 21: ECCS N°119 Worked Example 5

Project file: Benchmark_(EC_EN_1993)_21.esa

SCIA Engineer Version R18.1

Introduction

This benchmark concerns Worked Example 5 of ECCS N°119 Rules for Member Stability in EN 1993-1-1, Background documentation and design guidelines, ECCS, 2006.

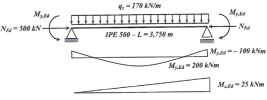

This fifth worked example deals with spatial behaviour. The beam-column is subjected to compression and biaxial bending. The transverse loading is assumed to act through the shear center. Lateral torsional buckling is a potential mode of failure according to the shape of the cross-section.

The interaction factors kij for combined bending and compression are determined using both alternative method 1 (Annex A) and alternative method 2 (Annex B).

Reference Results

The reference gives following results:

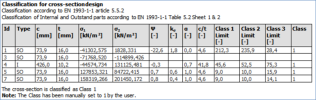

Classification:

|

Flanges |

|

| c/tf | 4,6 |

| Class 1 limit | 9,0 |

| => Flanges Class 1 | |

| Web | |

| c/tw | 41,8 |

| Class 1 limit | 45,6 |

| => Web Class 1 | |

| Compression resistance | |

| Nc,Rd | 2715 kN |

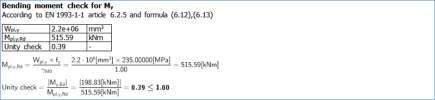

| Bending resistance | |

| Mc,y,Rd | 516 kNm |

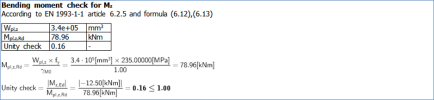

| Mc,z,Rd | 78,9 kNm |

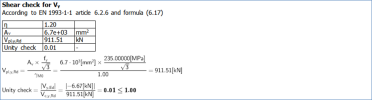

| Shear resistance | |

| Av,z | 5990 mm² |

| Vpl,z,Rd | 814 kN |

| Av,y | 6718 mm² |

| Vpl,y,Rd | 912 kN |

| Shear buckling does not need to be considered | |

| Resistance to combined bending, shear and axial force | |

| My,N,V,Rd | 516 kNm |

| Mz,N,V,Rd | 78,9 kNm |

| α | 2 |

| β | 1 |

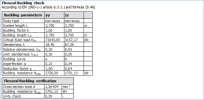

| Member buckling resistance in compression | |||

| Ncr,y | 71038 kN | Ncr,z | 3157 kN |

| Relative slenderness λy | 0,195 | Relative slenderness λz | 0,927 |

| αy | 0,21 | αz | 0,34 |

| χy | 1,00 | χz | 0,644 |

| Member buckling resistance in bending (General) | |

| C1 | 1,2 |

| Mcr | 1079 kNm |

| Relative slenderness λLT | 0,691 |

| Alpha_LT | 0,34 |

| Chi_LT | 0,789 |

| kc | 0,907 |

| f | 0,955 |

| Chi_LT,mod | 0,826 |

| Member buckling resistance in bending (Rolled) | |

| Relative slenderness λLT | 0,697 |

| αLT | 0,49 |

| χLT | 0,827 |

| kc | 0,907 |

| f | 0,954 |

| χLT,mod | 0,867 |

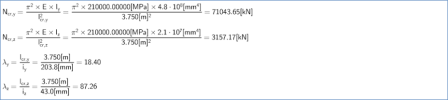

| Verification according to Method 1 | |

| μy | 1,00 |

| wy | 1,138 |

| μz | 0,937 |

| wz | 1,5 |

| Cmy,0 | 0,999 |

| Cmy | 1,00 |

| Cmz,0 | 0,771 |

| Cmz | 0,771 |

| Mcr,0 | 899 kNm |

| λ0 | 0,757 |

| aLT | 0,998 |

| bLT | 0,043 |

| cLT | 0,468 |

| dLT | 0,347 |

| eLT | 0,719 |

| Cyy | 0,981 |

| Cyz | 0,863 |

| Czy | 0,843 |

| Czz | 1,014 |

| eq. (6.61) | 0,964 |

| eq. (6.62) | 0,870 |

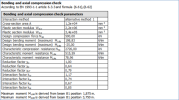

| Verification according to Method 2 | |

| Cmy | 0,925 |

| Cm,LT | 0,925 |

| Cmz | 0,6 |

| kyy | 0,924 |

| kyz | 0,489 |

| kzy | 0,961 |

| kzz | 0,815 |

| eq. (6.61) | 0,752 |

| eq. (6.62) | 0,974 |

SCIA Engineer results

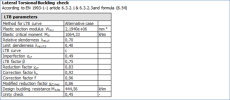

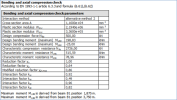

Verification according to Method 1:

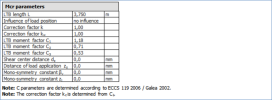

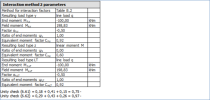

Verification according to Method 2:

Comments

- The results correspond to the benchmark results.

- The classification in the Reference uses for the stability checks class 1 determined from the section checks. SCIA Engineer uses for the stability checks the most negative class along the member (Class 3) but this has been manually modified to class 1 in order to have the same classification as the Reference.

- There are some small round-off differences between the cross-section properties. In SCIA Engineer the cross-section according to the Arcelor catalogue has been used.

- The reference calculates a wrong value for the shear area in the shear resistance check. The result shown above for the shear area is that corrected by manual calculation.

- In the verification according to method 1, the reference uses the ‘General Case’ for LTB. However, the reference also applies the reduction factor f to calculate Chi_LT,mod in this case. In EN 1993-1-1 this reduction is only specified for the ‘Rolled sections and equivalent welded sections Case’ and not for the ‘General Case’. Due to the differences in the LTB reduction factor, the eventual verification formulas have differences.

- In the verification according to method 1, both the reference and SCIA Engineer use the modified formula for calculation of Czz.as given in correction sheet EN 1993-1-1:2005/AC:2009.